In 2023, as part of DPH Bio’s commitment to expanding on-farm value, the company introduced RegenAphex®, its biological technology platform that acts as a foundational building block to biological product development to deliver easy-to-use products with a high efficacy in most growing environments. RegenAphex is produced regeneratively, through a proprietary plant-based composting and extracting process. It delivers readily available carbon and a consortium of microorganisms known to improve soil health, increase crop nutrient uptake and support plant health. The company’s flagship biofertilizer, TerraTrove™ SP-1 Classic™, is built on RegenAphex technology. The next generation of SP-1 will be introduced in a concentrated version named AmplAphex™ for the 2025 crop season, a powerful and proven testament to the success of the formulation.

Driven by consumer demands, changing climates and dwindling natural resources, regenerative agriculture is growing rapidly. The regenerative agriculture marketplace is projected to reach $24 billion in global revenue for 2030, growing at 14.4% CAGR, according to a recent market report.

Delivering a Sustainable Humus Extract Technology Platform for Broad Acre Production

RegenAphex will serve as DPH Bio’s foundation for novel solutions, revolutionizing how growers and horticulturists manage fertility and plant health while providing an environmentally friendly, domestically produced solution. Additionally, DPH Bio is making the RegenAphex platform available to enhance the performance of other microbial products in the market through third-party collaborations.

“What excites me the most about this dynamic technology is that it seamlessly fits into modern production practices, balancing performance, sustainability and scalability,” said Mick Messman President and CEO for DPH Bio. “We take a lot of pride in the fact that it is a renewable resource produced right here in the heartland, which allows us to mitigate the uncertainty and complexity of today’s global supply chain.”

Indeed, there are other humus-based biological products derived from humic substances, the major components of natural organic matter (OM) known for their ability to improve soil’s physical and chemical properties.

However, RegenAphex is a shelf stable liquid extracted from a plant-based humus itself. Unlike other humic substances available to growers, including humic and fulvic acids, RegenAphex is far more than just a soil conditioner. RegenAphex provides both soil and crop health benefits including as a super food base of readily available organic carbon needed to support a consortium of microorganisms.

Methodology

RegenAphex is made exclusively at DPH Bio’s 40-acre composting site and production facility using equipment developed specifically for DPH Bio’s proprietary humus extraction process.

While the initial process was developed by its legacy company, DPH Bio’s current technology and production teams have refined the composting production and plant-based compost process, setting the stage for the commercialization and scaling of the RegenAphex Technology Platform into new crops and geographies. Still today, DPH Bio’s Princeton, Illinois-based facility is the largest exclusively plant-based composting facility for agriculture in the United States, using no manure inputs in the composting process, thus ensuring a food safe finished product.

To produce RegenAphex, DPH Bio grows the source material that serves as the basis for its humified extract on neighboring no-till farmland. RegenAphex is made from a mixture of proprietary plant material, combined into carefully maintained compost piles to produce commercial scale quantities annually. The proprietary composting process pulls in micronutrients and provides a natural habitat for living microbes. The fine, granular product produced through this composting process becomes the nucleus of the humus.

The next step is liquifying the humus through a proprietary extraction process that preserves and extracts both soluble and suspensible minerals, humus proteins, humic substances, enzymes and microbes from the compost. The result is a clean, light brown water extract that is ultimately transferred to the market in a variety of easy to use, liquid packages ranging from 2 x 2.5G jugs to bulk. The entire extraction process takes roughly 10 to 12 weeks, which is significantly faster than others.

Additionally, DPH Bio’s proprietary process results in a stable product with a two-year shelf-life that remains viable even through freeze and thaws and is compatible with industry leading fertilizers. This is a vast improvement as compared to ‘brewed’ liquid products hosting microbial populations that typically have a short shelf life and require special handling, including refrigeration, to maintain the benefits of live microbials.

Along with being a powerful product for soil health in and of itself, RegenAphex is a proven, stable host for additional product development. For example, although it is made up of 75% RegenAphex, DPH Bio’s SP-1 Classic includes Plant Growth Promoting Rhizobacteria (PGPRs) and algae for an additional microbial food source. RegenAphex is also proven to be tank-mixable, and can be safely combined with other inputs, including conventional chemistry-based inputs. This makes RegenAphex unique and an innovative building block for future biological formulations.

Results

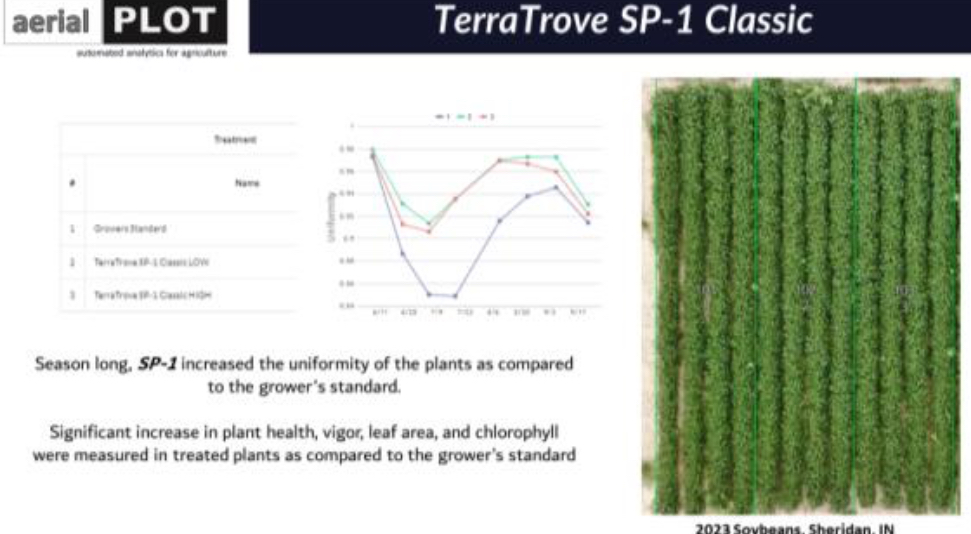

Powered by RegenAphex, SP-1 Classic has consistently unlocked the soil and plant health benefits of a thriving ecosystem for water, nutrient and microbial exchange, supporting and preserving yield potential while enabling increased crop growth and resiliency. Not surprisingly, as a humus-based extract, SP-1 Classic has reliably returned the soil health benefits typically associated with humus’ crucial role in soil and plant health, including improving soil structure and reducing erosion by binding together soil aggregates for larger soil particles; storing and releasing water by acting as a sponge, absorbing into the soil and releasing it during dry periods; and creating the habitat for soil microbes to cycle nutrients through the soil, making them plant available.

For instance, in a 3-year grower partner field trial, growers using SP-1 Classic in-furrow with their fertilizer application found two times faster water into soil infiltration; 70% better aggregate stability in low-aggregate soils and 10% lower soil bulk density contributed to reduce soil compaction.

Additionally, RegenAphex (through SP-1 Classic applications) has proven to support faster and better crop emergence, consistently averaging 900 more corn plants per acre in a cross-trial summary across nine locations.

RegenAphex based products have proven to have benefits across a spectrum of tillage and production practices when used as a soil application. Looking at yield, which is supported by a complex association of factors, a metadata analysis of 107 corn trials conducted over three years using SP-1 Classic, revealed increased ROI tied to specific practice recommendations, depending on a grower’s tillage practices. For example, in a multi-year study across 21 locations on tilled soils, SP-1 had a 76 percent win rate with an average yield increase of 3.5 bushels per acre. Further analysis shows that SP-1 had a higher win rate and incremental yield in high yield environments. SP-1 averaged 6.5 more bushels per acre in high-yield, 220-bushel per acre or more corn across the Midwest. In addition, a 2023 in-furrow trial collaboration with the University of Illinois showed a 7.3 per bushel response when SP-1 Classic was added into a grower’s standard practice.

When used as a foliar, RegenAphex (through SP-1 Classic application) has decreased the impact of abiotic stress and supported crop reproductive processes, helping growers preserve their yield even through drought or extreme weather conditions. It does so by applying microorganisms to plants to naturally produce phytohormones and enzymes that inhibit ethylene production, a hydrocarbon that accelerates plant maturation. The microorganisms in RegenAphex also support the pathways that increase osmolytes. Osmolytes enhance plants’ potential to preserve water without impacting metabolism under drought, heat and salinity stress. In addition, osmolytes protect plant cells from oxidative damage by inhibiting the production of Reactive Oxygen species (ROS). Field trials have shown faster wheat green-up after SP-1 Classic foliar application on winter wheat, and increased yields in soybeans (9% over the check), potatoes (18.7% over the check), wheat (3.9 bushel increase over check) and corn (12.5% increase over check) when treated with post-emergence applications.

The RegenAphex platform, as shown through the wide-spread use and field trial data collected on SP-1 Classic, has well-proven soil and plant benefits across a spectrum of production practices, crops, soil types and through a variety of application practices – delivering on the promise of biologicals to growers, the supply chain, and ultimately consumers.

Conclusions

Biologicals have been available to growers for many years, but broad adoption has been limited due to technology and application challenges. As demand for a more safe and nutritious food supply increases, growers must have access to biologicals that work. To meet the demand, innovation – by DPH Bio as well as its partners – can be accelerated powered by RegenAphex. Yield and ROI are now table stakes that all biological products must provide. But it is the larger, holistic slate of soil and crop health benefits, and economic and societal benefits that biologicals uniquely offer that can generate the step-change impact for more sustainable and resilient food production. However, those benefits must be provided with products that are easy-to-use and adopt within farmers current practices and equipment, or the barriers will remain.

By harnessing and building upon the power of humus, oftentimes referred to as the “life force” of the soil, in a plant-based, regeneratively produced and scalable liquid extract form, RegenAphex is uniquely positioned to give the biological industry a building block to future biological innovation supporting the sustainable, resilient and safe food production system. DPH Bio aims to rapidly build upon its RegenAphex technology platform through owned and collaborative product development to inspire future innovation.

Leave a Reply